It seems like just a few weeks ago that I replaced the spherical bearings on my ADS coilovers for the first time, though it turns out, it was actually a few (4) months ago. Prior to that, I'd put some 27K miles on the new ADS suspension (see installation) - miles that really proved to me that it was a worthwhile investment.

Unfortunately, on our last trip down to the Eastern Mojave, the coilovers had been squeaking again. Well, really they'd been squeaking before we even left - but with only 7K miles on the odometer since the previous change, hoped it was just the springs squeaking as they compressed and extended. By the time we got back, another 2500 miles behind us, I knew that wasn't it - the sound was coming from the bearings - again.

Now - a regular reader may recall that last time when I did this job, it wasn't just the spherical bearings that needed replacement, it was also the misalignment spacers and lower shock bolts - the spherical bearings being so worn that they'd caused the other components to fail as well.

I learned last time - procrastination can be costly.

Not wanting the same thing to happen this time, I set about the familiar process of removing the front suspension so I could press out the worn bearings. More details on that are available in my first replacement, and I was happy to see that this time none of the retaining clips had broken, allowing easier access to the spent bearings using my Channellock 927 8-inch snap ring pliers.

A bit of press work, and the first side was disassembled. I took some time to inspect the hardware.

There are a few things worth noting here:

- The spherical bearing is clearly shot. Check out the filaments that are seemingly escaping from between the race and the ball. Interesting, no? Note: more on this later.

- The misalignment spacers are in much better condition than the last time I did the job, but you can see what looks to be a bit of wear on the interior surfaces. I couldn't feel any irregularities however, and I believe that some of what we see there is actually mineral residue from water that evaporated after I washed the truck.

- The bolts are in better shape, but you can definitely see where the misalignment spacers were seated on the bolts, with a bright line around the circumference of the shaft, where the spacers don't quite touch as they are inserted into the ball.

As one does - despite the expense of the shocks - I cheaped out decided to save a whopping $21 and re-use the misalignment spacers, lower bolt, and clips rather than replacing them with new. I set about pressing the new spherical bearings into the races - an easy job with the 20-ton press.

From there, I was able to reasonably easily re-mount the shocks - a process that I've grown to loath due to the inconvenient top-of-the-frame mounting location for the remote reservoirs - and wash a significant amount of mud off the inside of the wheels (left over from the Mojave trip and messing with my wheel balance at 65mph), before getting them remounted and eventually torqued.

Torque specs - for anyone interested - on this job are:

- Three (3) nuts on the shock top hat: 47 ft-lbs

- Lower shock mount bolt: 101 ft-lbs

- Wheel lug nuts: 89 ft-lbs

With everything put back together and ready for the next adventure - whenever that may be given these crazy times (!) - I found myself wanting to understand how these spherical bearings worked (at least a little better) since they seemed to last... not a long time.

Why do these things fail so quickly?

Onto the interwebs I travelled, precious little data available on the expected lifetime of these little buggers. In the end, info was so sparse that it's hard to even link to a few good sources, but here's a diagram I put together with what seem to be the important bullet points.

So, the key to the lifetime of a spherical bearing - at least one with a "T" designation, such as COM10T - is keeping the Teflon liner in good shape. As long as it is functioning, you'll have a quiet joint that's working as designed. However, as soon as that fabric/liner starts to get chewed up - usually from mud or muddy water introduced via off-road conditions - the entire bearing is on borrowed time; less than a few thousand miles - at most - until it needs to be replaced. That Teflon liner is what I captured above as filaments coming out of the spherical bearing.

Now, you may say to yourself, "What?! Why do these expensive race-style shocks use such a temperamental part?" The answer is right there in the question: because these are expensive, race-style shocks. These ADS shocks - but also King's, Icon's, Fox's, etc. - anything with spherical bearings at the lower mount - were originally designed for use by high performance race trucks. On those trucks, teardowns and rebuilds - especially of the suspension - are a regular maintenance item that takes place after every race. Every few hundred - or a thousand - miles at most. The two goals of these shocks are performance and rebuildability.

By design then, the spherical bearing does a great job of allowing really good articulation and tight tolerances, but at the expense of longevity if the joint gets dirty. A rebuild of the lower mount runs between $15 and $60 depending on how much of it you have to replace, and must be performed every 7K-15K miles.

A typical spherical bearing joint rebuild kit - the bearing itself, misalignment spacers, and retaining clips.

Compare that to OEM shocks, or mid-tier replacements (Bilstein, OME, etc.). These last longer - 30K to 60K miles - by using rubber bushings rather than steel parts, but those bushings allow for much more play in the joint and aren't rebuildable - at least, not usually or easily. Instead, replacement of the shock is necessary - running on the order of $300 or so (if you keep your existing springs) or $800 if you purchase new coilovers.

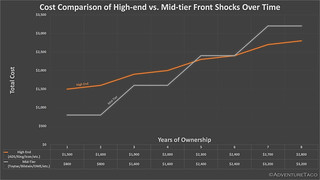

For me, with the number of miles I put on the truck, the racing shocks turn out to be cheaper in the long run. With 3 bearing replacements a year I will spend ~$100/year (and time!) keeping them in top shape (plus internal rebuilds every couple years). Compare that to rubber-bushing based shocks that I would have to replace every two years - or between $150 and $400/year. And sure, there was that initial outlay for the ADS shocks, but it wasn't all that much more than the Toytec BOSS kit that I installed a couple years earlier... and they were worn out when I removed them.

Anyway, here's a chart for the data geeks - and cheapos  - like me that does a cost breakdown over time. Six years is about the break-even point, though it gets close around three years.

- like me that does a cost breakdown over time. Six years is about the break-even point, though it gets close around three years.

How's that saying go? Buy once... cry as you keep on paying...