Over the last couple years, I've learned - mostly from others experience - that it's a good idea to keep an eye on 1st gen Tacoma lower ball joints (LBJs). If you do lots of bumpy, off-road style driving, every 30-50,000 miles is a reasonable interval to change this part of your truck, in order to prevent a catastrophic failure.

So, today I headed out to the shop to check my LBJs, and here's what I found. This time, it's been 15 months, and it's definitely time for replacement. Before you do this test, you want to jack up the front truck of course.

Parts

The first step in any project like this is gathering the parts and tools. Parts are straight forward - you need ball joints and bolts. I always use and recommend OEM LBJs, since other brands are known to have premature failure.

Tacoma

When purchasing OEM LBJs, you have several choices on a 1st gen 4WD Tacoma (or Prerunner). Each of these options include exactly the same Lower Ball Joints. Personally, I tend check prices on all of these and then purchase the cheapest L and R option, depending on whether I am replacing the bolts as well.

- If you also need 4 bolts, then you have two choices:

- Best: If you'd like to use the (better) "Black" bolts (w/washer) to secure the LBJ to the lower control arm (LCA), purchase LBJs and bolts separately:

- LBJs - L: 43340-39436; R: 43330-39556.

- "Black" bolts - 8 of 90119-10933

- Good: A kit that includes "Green" flanged bolts to secure the LBJ to the lower control arm (LCA), are sold as part numbers - L: 43340-39585; R: 43330-39815.

- Best: If you'd like to use the (better) "Black" bolts (w/washer) to secure the LBJ to the lower control arm (LCA), purchase LBJs and bolts separately:

- If you plan to re-use your 4 existing LBJ bolts (generally only OK with the "black" bolts), then you can usually save a bit of money and get - L: 43340-39436; R: 43330-39556.

- Toyota has a recall on some model year Tacoma LBJs. If you can find Lower Ball Joint TSB Kit (Left+Right: 04005-03235), it is sometimes cheaper. However, note that it does not come with LBJ bolts or castle nuts.

4Runner

Unlike the Tacoma, there's really only one choice of LBJ for the 4Runner, making things easy.

- For a 4Runner, bolts are always sold separately. You should purchase

- LBJ part numbers - L: 43340-39465; R: 43330-39585.

- "Black" bolts - 8 of 90119-10933

Bolts

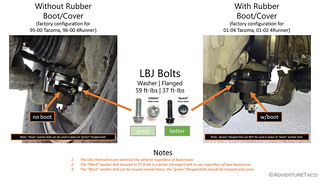

There are several options on bolts, and @SpikerEng did a great analysis of each option. This is recommended reading due to the importance of LBJs, but if you'd rather not read it, the conclusion was that the best bolts are properly torqued (37 ft-lbs) black bolts (90119-10933) that were introduced for later models (01-04 Tacoma, 01-02 4Runner) when the LBJ dust boot was added.

If you need bolts and don't purchase the LBJs that include them, then you also have two options:

- If you do not have a rubber dust covers on your LBJs, you need

- best - eight (8) "black" (washer) or

- good - eight (8) "green" (flanged) bolts.

- If you do have a rubber dust covers on your LBJs, you need eight (8) of "black" (washer) bolts.

Note: You will end up with a stronger LBJ - regardless of rubber dust cover use - by using the black bolts. That is because they create a tighter joint when torqued to 37 ft-lbs than the older, "green" flanged head bolts (which were torqued to 59 ft-lbs).

Additionally, the "green" flanged head bolts should only be used once, while the "black" bolts can be reused several times.

- "Green" Flange Head LBJ Bolt (90105-10406). These bolts are torqued to 59 ft-lbs.

- "Black" Washer LBJ Bolt (90119-10933). These bolts are torqued to 37 ft-lbs.

Tools

From a tools perspective, I mostly ended up using several sockets, a ball joint separator, and my impact and torque wrenches:

- Misc sockets (set)

- 22mm socket (19mm for 4Runner) to remove the castle nut on the outer tie rod

- 24mm socket to remove the castle nut on the LBJ

- 14mm socket to remove the four bolts holding the LBJ to the spindle

- OTC 6295 Front End Service Set

- pliers for the various cotter pins (cutting) (needle nose)

- Milwaukee mid-torque impact wrench

- A torque wrench for re-installation of critical components.

- A floor jack and jack stands.

- A bit of blue Loctite (242)

- New cotter pins (this assortment is good)

Doing the Job

With everything in hand, the replacement process is reasonably straight forward. First, jack up the front of the truck and support it securely on jack stands. Remove the wheels. Now, with access to the hub assembly, remove the 4, 14mm bolts that secure the LBJ to the hub.

Next, remove the cotter pin and loosen - but do not remove - the 24mm castle nut that secures the LBJ to the lower control arm (LCA).

By loosening, but not removing the castle nut, you can keep the joint from jumping too much in the following step. This is the point at which you want to use a pitman arm puller to push the stud of the LBJ out of the LCA.

Next, repeat the cotter pin, castle nut, and pitman arm puller process on the 22mm castle nut that secures the steering (outer tie rod) to the LBJ. (Note: this is 19mm castle nut on a 4Runner.)

At this point, you can simply lift the hub assembly up and out of the way, in order to remove the old LBJ from the LCA.

Installation of the new LBJ is also straight-forward and essentially the reverse of removal. In fact, it all went so quickly that I only snapped a couple photos. However, the steps and torque specs were:

- Position the new LBJ between the spindle and LCA, careful to use the side-appropriate part. At this point, you can set the hub assembly back in place to relieve a bit of the stress the CV axle boots are likely experiencing.

- Install the new 24mm castle nut that secures the LBJ to the LCA and hand tighten. Don't torque it yet.

- Install the old 22mm castle nut (19mm on a 4Runner) that secures the outer tie rod end to the LBJ and hand tighten.

- Install four new 14mm bolts through the LBJ and into the spindle. Tighten them reasonably tight to ensure everything is aligned correctly

- Back out one 14mm bolt at a time to apply some blue Loctite and torque to 59 ft-lbs (flange head w/o dust cover) or 37 ft-lbs (washer-based w/dust cover).

- Torque the castle nut that secures the LBJ to the LCA to 103 ft-lbs (plus any additional necessary to allow installation of the cotter pin).

- Torque the castle nut that secures the tie rod end to the LBJ to 67 ft-lbs (plus any additional necessary to allow installation of the cotter pin).

And then it's done!

Hey, anyone interested in purchasing some low-mileage, never-seen-dirt, OEM lower ball joints for a great price before they go on Craigslist as "like new"? I'll even throw in four bolts, a couple castle nuts, and one cotter pin for the same low, low price!

Relax internet, I'm kidding.

Replace those LBJs!

Step-by-Step Replacing Lower Ball Joints (LBJ) on a 1st Gen Tacoma (or 3rd Gen 4Runner) - Over the last couple years, I've learned - mostly from others experience - that it's a good idea to keep an eye on 1st gen Tacoma lower ball joints (LBJs). If you do lots of bumpy, off-road style driving, every 30-50,000 miles is a reasonable interval to change this part…

Step-by-Step Replacing Lower Ball Joints (LBJ) on a 1st Gen Tacoma (or 3rd Gen 4Runner) - Over the last couple years, I've learned - mostly from others experience - that it's a good idea to keep an eye on 1st gen Tacoma lower ball joints (LBJs). If you do lots of bumpy, off-road style driving, every 30-50,000 miles is a reasonable interval to change this part… Choosing Lower Ball Joint (LBJ) Bolts - The content in this guide was originally created by Leon @SpikerEng on TacomaWorld as a series of posts over several months. I've captured it here for two reasons: I want to make sure that, should anything happen to Leon's post, that we all still have access to this amazingly useful…

Choosing Lower Ball Joint (LBJ) Bolts - The content in this guide was originally created by Leon @SpikerEng on TacomaWorld as a series of posts over several months. I've captured it here for two reasons: I want to make sure that, should anything happen to Leon's post, that we all still have access to this amazingly useful…

Thank you for putting this information into a clear concise format. I've been reading forums all day, didn't know what to buy for LBJs. Also just purchased your Tacoma to Tundra brake line kit and it works great. Thank you for being an invaluable member of the community!

Oh man, thanks for the kind words, I really appreciate them. I’ve learned so much from the community as I got into my Tacoma that it’s been nice to be able to give back a bit.

If you have a chance, I'd love a positive review on Google, it turns out they help with search results lot more than I originally realized they do!

And as always, please feel free to reach out any time with questions - I'm always happy to help with this stuff!